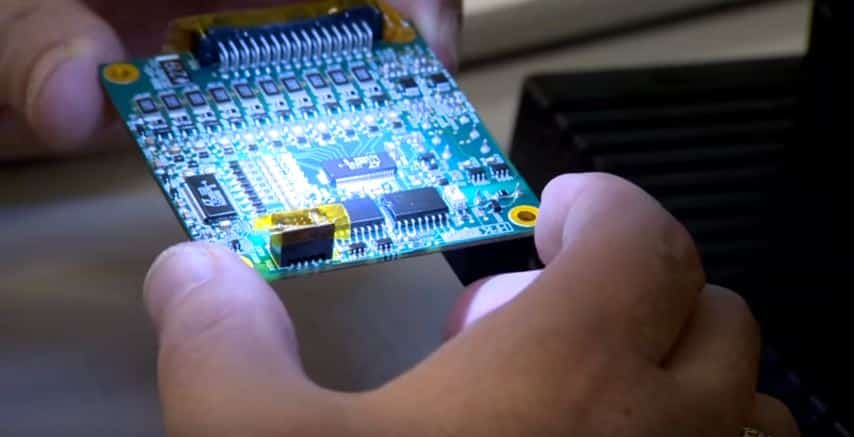

FINAL BOX BUILD & TEST

We at Hallmark Electronics Ltd pride ourselves on providing a most comprehensive final box build and testing service that ultimately minimizes supply chain risks and reduce total project costs.

Being one of the first operations based in the UK to truly boast in-house PCB Manufacturing facility, component kitting and also both Electronic/Mechanical assembly departments all housed in the same building; we can offer flexibilities and efficiencies to reduce the logistic strain of supply.

The box build assembly work is executed in a separately dedicated cell, specially equipped to maximize efficiency, with an emphasis on quality, care and above all, protection of the product.

We regularly manufacture a wide range of mechanical assemblies and also integrated system activities. This starts with PCB Manufacture and Assembly, cable assembly, membrane keypads, metalwork preparation (metal/plastics), including machining, drilling etc and often finished in both paint/screen printing before the final test.

The real benefit and feedback we have received from customers suggest the placing of one purchase order to then receive the complete and finished unit or product is a massive saving in resources and cost.

“Thank you to all the Team at Hallmark, you’ve made what I thought a difficult job seem easy and I’m very happy with overall quality”

IN NEED OF SOME HELP?

CONTACT US

Approved By: